How are Photovoltaic Solar Panels Made

How are Photovoltaic Solar Panels Made

Photovoltaic solar panels, also known as solar PV panels, are a type of device that converts sunlight into electricity. These panels are an essential component of solar energy systems and are widely used to generate clean and renewable energy. But have you ever wondered how these solar panels are made? In this article, we will explore the process of making photovoltaic solar panels.

The Basic Components of Photovoltaic Solar Panels

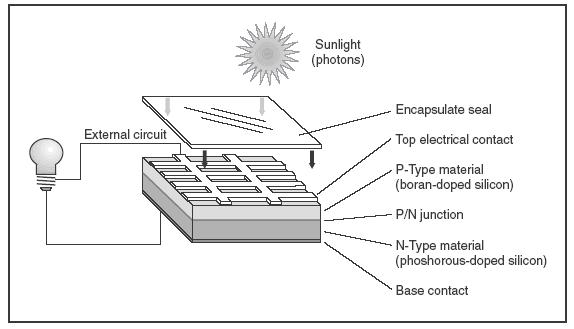

Before delving into the manufacturing process, it’s important to understand the basic components of photovoltaic solar panels. These panels are typically made up of solar cells, which are the building blocks that convert sunlight into electricity. The solar cells are usually made of silicon, a semiconductor material that has the unique property of generating an electric current when exposed to sunlight. In addition to solar cells, solar panels also consist of a protective glass cover, a frame for support, and wiring to connect the panels to an electrical system.

Silicon Ingot Production

The first step in the manufacturing process of solar panels involves producing silicon ingots. This is done by melting high-purity silicon in a crucible and then slowly cooling it to form a solid block or ingot. This process is known as the Czochralski method and helps to ensure that the silicon ingots have a uniform crystalline structure, which is crucial for their performance in solar cells.

Solar Cell Fabrication

Once the silicon ingots are produced, they are sliced into thin wafers using a wire saw. These wafers undergo a series of manufacturing steps, including texturing, doping, and metallization, to create the solar cells. During the texturing process, the surface of the silicon wafer is roughened to enhance light absorption. Doping involves introducing impurities into the silicon to create the necessary electrical properties, while metallization involves adding the contacts for electrical connections.

Solar Panel Assembly

After the solar cells are fabricated, they are assembled into solar panels. This involves placing the solar cells onto a backing material, such as a sheet of glass, and connecting them together using conductive adhesive. The solar cells are then encapsulated with a protective material, such as ethylene vinyl acetate (EVA), and a top layer of tempered glass is added to protect the cells from external elements.

Quality Control and Testing

Before the solar panels are ready for deployment, they undergo rigorous quality control and testing procedures to ensure their performance and durability. This involves electrical testing, visual inspection, and performance testing under simulated sunlight conditions. Only panels that meet the strict quality standards are approved for installation.

Conclusion

In conclusion, photovoltaic solar panels are made through a series of intricate manufacturing processes that involve producing silicon ingots, fabricating solar cells, assembling solar panels, and conducting quality control and testing. These panels play a crucial role in the generation of clean and sustainable energy and continue to contribute to the global transition towards renewable energy sources.