Photovoltaic cells, also known as solar cells, are the building of solar panels and are crucial in the generation of renewable energy. Have you ever wondered how these important components are made? In this article, we will explore the process of manufacturing photovoltaic cells.

Materials Used in Photovoltaic Cell Production

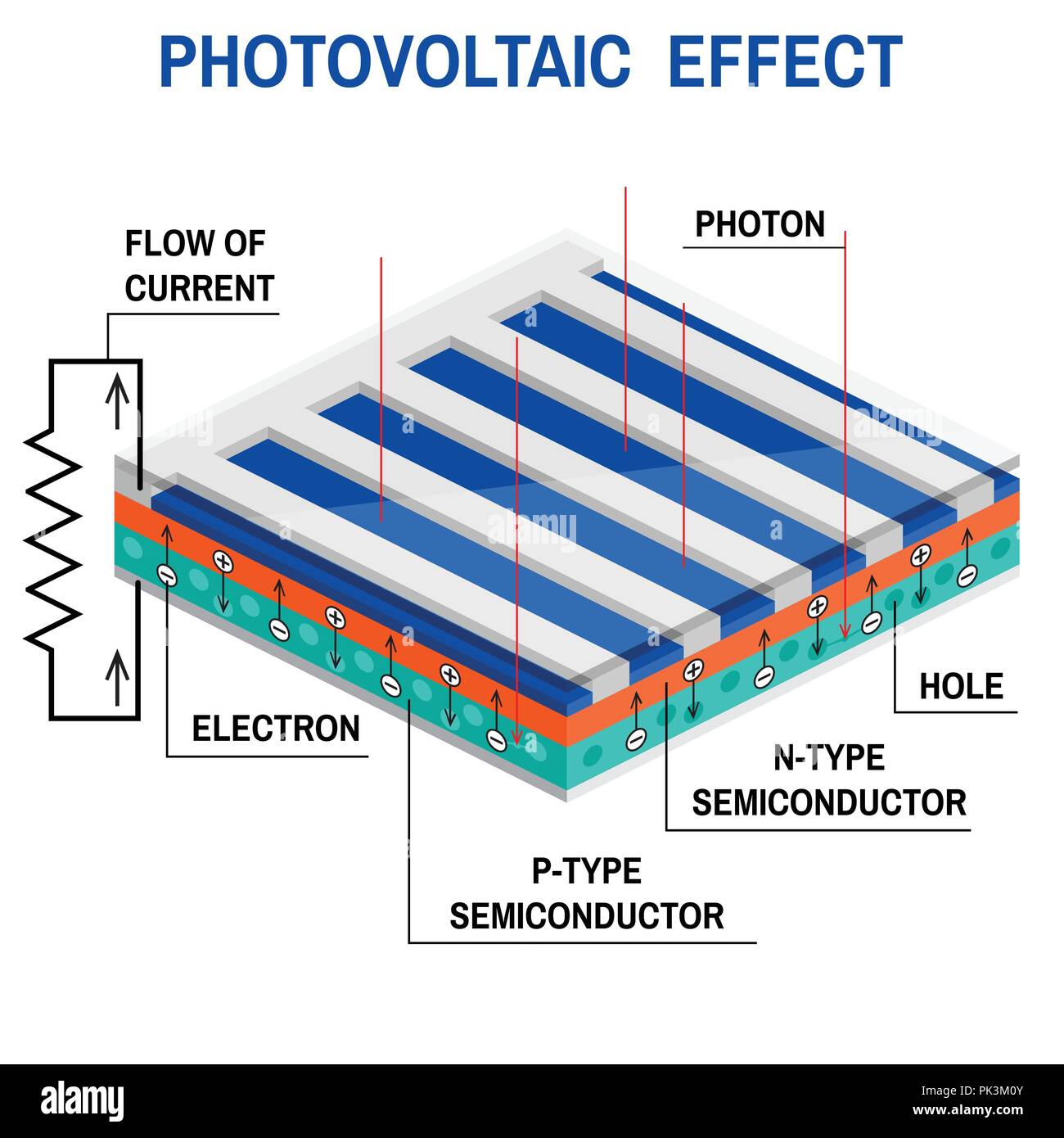

The manufacturing of photovoltaic cells begins with the selection of high-quality materials. The key components include silicon wafers, which are typically made from crystalline silicon. These wafers are the foundation of the cell and are responsible for converting sunlight into electricity. In addition, other materials such as metal conductors, glass, and anti-reflective coatings are also used in the production process.Production Process

1.Wafer Production

The first step in manufacturing photovoltaic cells involves the production of silicon wafers. This process begins with the purification of silicon, which is then formed into ingots. These ingots are then sliced into thin wafers using a process known as wire sawing.2.

Cell Assembly

Once the wafers are prepared, they undergo a series of steps to form the photovoltaic cell. The wafers are doped with various elements to create a positive and negative charge, which is essential for the generation of electricity. Metal conductors are then applied to the top and bottom of the wafers to allow for the flow of electricity.

3.

Encapsulation

After the cells are assembled, they are encapsulated to protect them from the elements. This typically involves sandwiching the cells between layers of glass and a polymer material. This encapsulation not only safeguards the cells but also allows sunlight to reach the cells.4.