How Photovoltaic Cells are Made

Introduction

Photovoltaic cells, also known as solar cells, are the key component in solar panels. These cells are responsible for converting sunlight into electricity, making them an essential part of renewable energy generation. In this article, we will explore the process of how photovoltaic cells are made.

Raw Materials

The production of photovoltaic cells begins with the procurement of raw materials. The primary material used in the manufacturing of solar cells is silicon. High-quality silicon is obtained from quartzite, a type of rock that is rich in silicon dioxide. Other materials such as boron, phosphorous, and metals for contacts and gridlines are also sourced to create the various components of the photovoltaic cell.

Growing Silicon Ingots

The first step in the production of photovoltaic cells involves growing large silicon ingots. This process begins by heating purified silicon in a furnace until it reaches a molten state. The molten silicon is then slowly cooled and solidified to form a large single crystal ingot. This ingot is then sliced into thin wafers using a diamond saw.

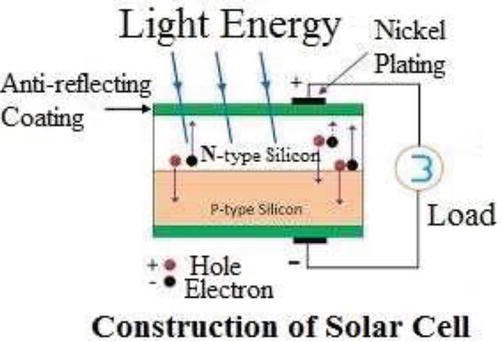

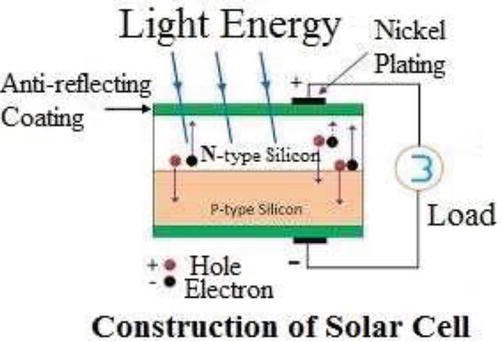

Doping the Wafers

The next step is to “dope” the silicon wafers with specific impurities to create N-type and P-type silicon, which are essential for the functioning of the photovoltaic cell. Phosphorous is typically used to create the N-type silicon, while boron is used for the P-type silicon. This process changes the electrical properties of the silicon, allowing for the creation of a junction within the cell.

Creating the Cell Structure

Once the silicon wafers are doped, they undergo a series of processes to create the cell structure. Metal contacts are screen-printed onto the silicon wafers, forming the positive and negative terminals of the cell. Additionally, gridlines are applied to better distribute the electrical current generated by the cell. These steps are crucial in maximizing the efficiency of the photovoltaic cell.

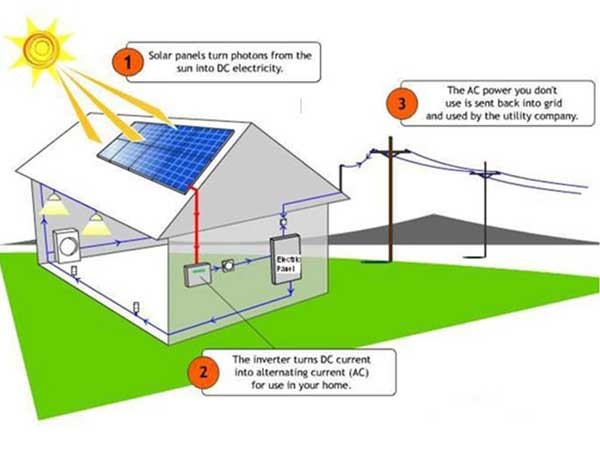

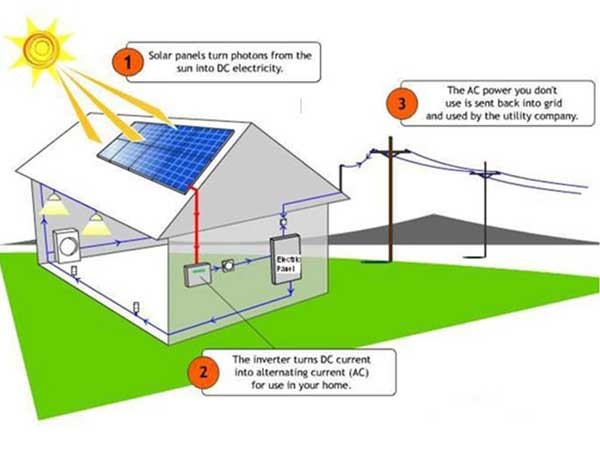

Encapsulation and Testing

After the cell structure is formed, the individual photovoltaic cells are assembled into solar panels. The cells are encapsulated in a protective layer to shield them from environmental factors such as moisture and dust. Finally, the assembled panels undergo rigorous testing to ensure their performance and durability before being made available for use in solar power systems.

Conclusion

The production of photovoltaic cells involves a precise and intricate manufacturing process. From growing the silicon ingots to encapsulating the cells into solar panels, each step is essential in creating high-quality and efficient solar cells. As the demand for renewable energy continues to grow, advancements in photovoltaic cell manufacturing will play a crucial role in transitioning towards a more sustainable energy future.