How to Make a Silicon Photovoltaic Solar Cell

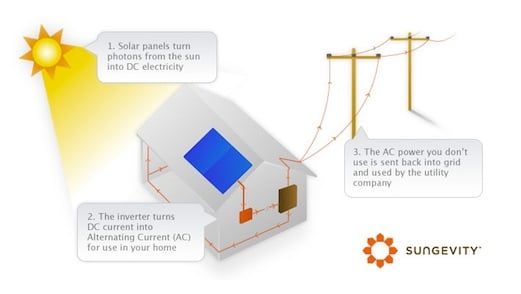

Silicon photovoltaic solar cells are an effective and popular way to harness the power of the sun and convert it into usable electricity. These solar cells are made using a process that involves several steps, including silicon wafer preparation, doping, and cell assembly. In this article, we will discuss the process of making a silicon photovoltaic solar cell.

Silicon Wafer Preparation

The first step in making a silicon photovoltaic solar cell is preparing the silicon wafers. These wafers are typically made from high-purity silicon that has been grown into ingots and then sliced into thin wafers. The wafers are then cleaned and polished to remove any imperfections and contaminants.1. Cleaning the Silicon Wafer

The silicon wafers are cleaned using a series of chemical and mechanical processes to remove any impurities and residues. This is crucial for ensuring the efficiency and effectiveness of the solar cell.

2. Texturizing the Silicon Wafer

After cleaning, the silicon wafers are texturized to create a rough surface that can trap more sunlight. This is usually done using a chemical etching process that creates microscopic pyramids on the surface of the wafer.Doping

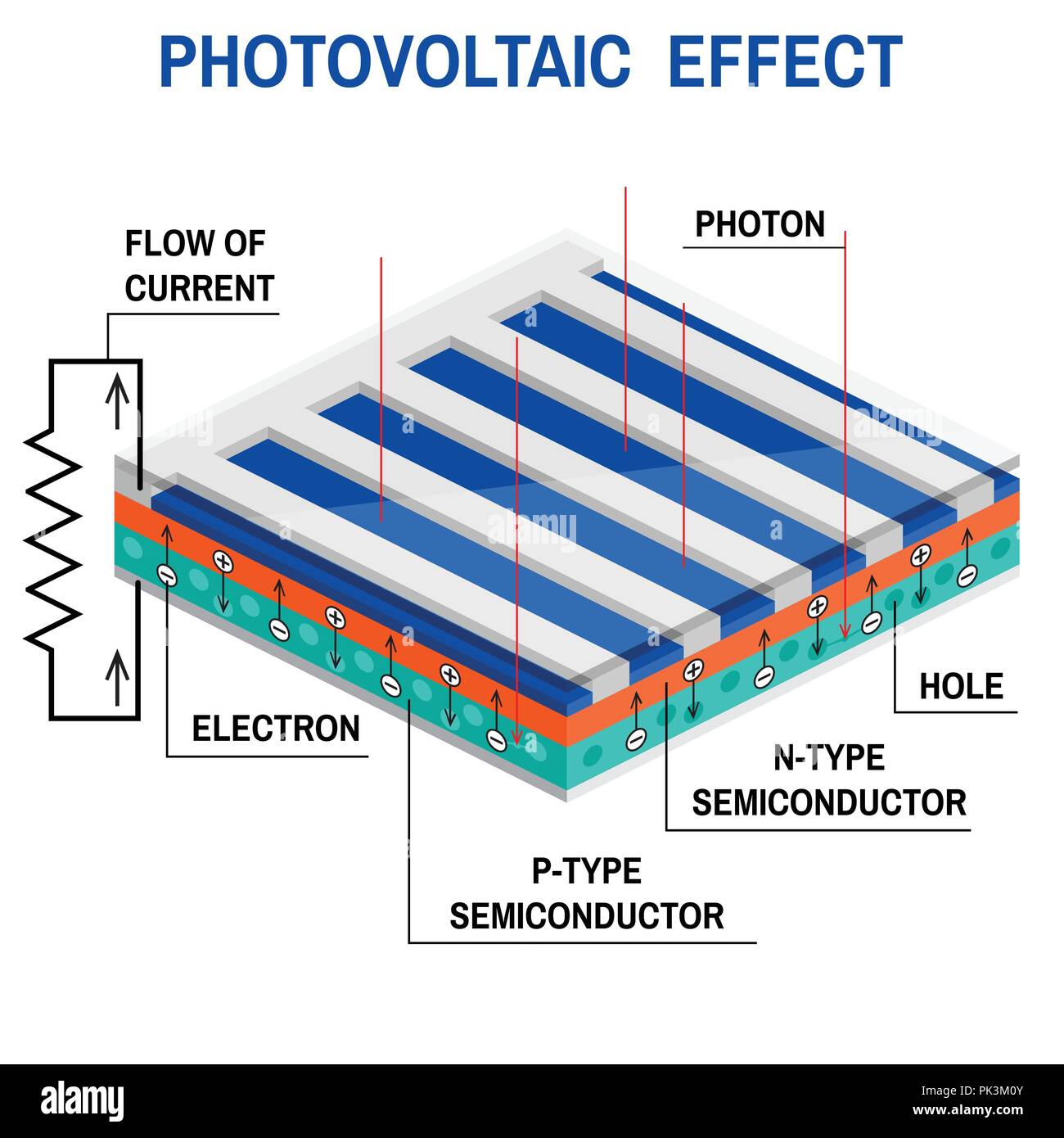

Doping is the process of introducing impurities into the silicon to create the n and p-type layers necessary for the functioning of the solar cell.3. N-type Doping

The n-type layer is created by introducing phosphorus atoms into the silicon wafer. This is typically done through a process called diffusion, where the wafer is heated in the presence of phosphorus gas.4. P-type Doping

The p-type layer is created by introducing boron atoms into the silicon wafer. This is also done through a diffusion process, but with boron gas instead.Cell Assembly

Once the silicon wafer has been prepared and doped, it is ready for cell assembly.5. Applying the Contacts

Metal contacts are applied to the front and back of the silicon wafer to allow for the flow of electricity. These contacts are typically made from a grid of fine metal lines that cover the entire surface of the wafer.In conclusion, the process of making a silicon photovoltaic solar cell involves several crucial steps, including silicon wafer preparation, doping, and cell assembly. By following these steps carefully, high-quality solar cells can be produced to harness the power of the sun and provide clean and renewable energy for various applications.