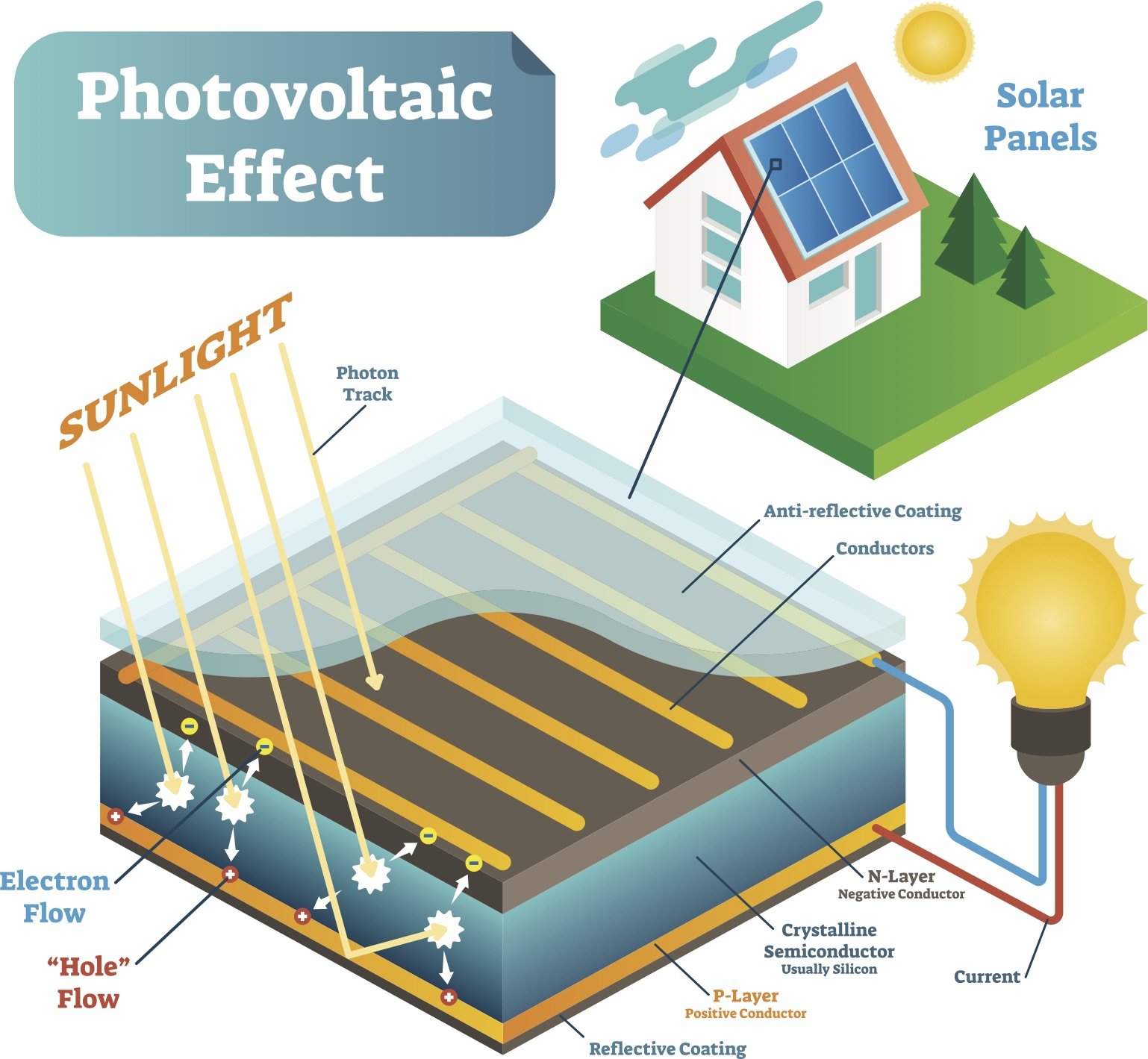

Photovoltaic cells, also known as solar cells, are devices that convert light energy into electrical energy using the photovoltaic effect. These cells are a crucial component of solar panels, which are used to capture and convert sunlight into usable electricity. In this article, we will discuss the process of making photovoltaic cells.

What are photovoltaic cells?

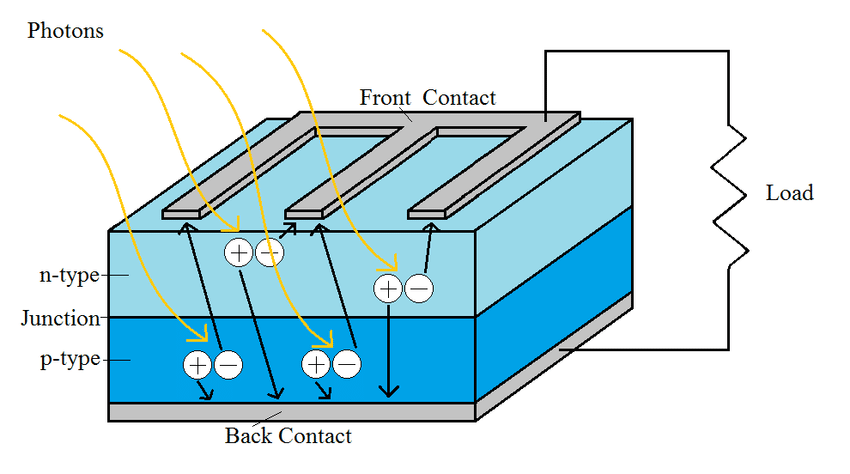

Photovoltaic cells are made of semiconductor materials, such as silicon, that can absorb photons and convert them into electron-hole pairs. When light strikes the surface of the cell, it excites the electrons in the semiconductor material, causing them to flow and create an electrical current. This process is the fundamental principle behind the operation of solar panels.Materials required for making photovoltaic cells

To make photovoltaic cells, you will need the following materials: 1. Silicon wafers: These are the basic building blocks of photovoltaic cells. They are typically made by slicing a single crystal of silicon into thin wafers. 2. Phosphorus and boron: These are used to create the p-n junction in the silicon wafer, which is essential for the photovoltaic effect to occur. 3. Anti-reflective coating: This helps to reduce the amount of sunlight that is reflected off the surface of the cell, allowing more light to be absorbed. 4. Electrical contacts: These are used to collect the electrical current generated by the photovoltaic cell.Step-by-step process of making photovoltaic cells

1. Cleaning and preparing the silicon wafers

The silicon wafers are cleaned to remove any impurities and then coated with a thin layer of phosphorus on one side and boron on the other. These layers create the p-n junction in the silicon, which is essential for the operation of the cell.