Photovoltaic ink, also known as solar ink, is a cutting-edge technology that allows for the generation of electricity using printable solar cells. This innovative ink can be used to create energy-efficient and cost-effective solar panels, as well as a wide range of other solar-powered devices. In this article, we’ll explore the process of making photovoltaic ink and the potential applications of this exciting technology.

What is photovoltaic ink?

Photovoltaic ink is a type of conductive ink that contains photovoltaic materials, such as organic photovoltaic or perovskite materials. These materials are capable of converting light into electricity, making them ideal for use in solar cells and other solar energy technologies. Photovoltaic ink can be applied using printing techniques, such as inkjet printing or screen printing, allowing for the creation of flexible and lightweight solar panels.How to make photovoltaic ink

The process of making photovoltaic ink involves several steps, starting with the preparation of the photovoltaic materials. These materials may be synthesized in a laboratory setting or purchased from a supplier. Once the materials are ready, they are combined with a conductive polymer and a solvent to create a homogeneous ink solution. The ink solution can then be loaded into a printer or other printing device for application onto a substrate, such as glass or plastic.Step 1: Synthesize or purchase photovoltaic materials

The first step in making photovoltaic ink is to obtain the photovoltaic materials. These materials may be synthesized using chemical processes in a laboratory, or they may be purchased from a supplier specializing in photovoltaic materials.

Step 2: Combine with a conductive polymer and solvent

Once the photovoltaic materials are ready, they are combined with a conductive polymer, such as poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS), and a solvent, such as ethanol or dimethyl sulfoxide (DMSO). This combination creates a homogeneous ink solution that is suitable for printing.Step 3: Load the ink into a printing device

The photovoltaic ink solution can be loaded into a printer or other printing device, depending on the chosen printing technique. Inkjet printing and screen printing are two common methods for applying photovoltaic ink onto a substrate.Step 4: Print onto a substrate

Finally, the photovoltaic ink is printed onto a substrate, such as glass, plastic, or even paper. Once the ink has been applied, it can be cured using heat or UV light to create a stable and functional solar cell.Step 5: Test and optimize the solar cell

After the ink has been applied and cured, the resulting solar cell can be tested and optimized for efficiency and performance. This may involve tweaking the ink formulation, as well as the printing and curing processes, to achieve the desired electrical properties and energy conversion efficiency.Potential applications of photovoltaic ink

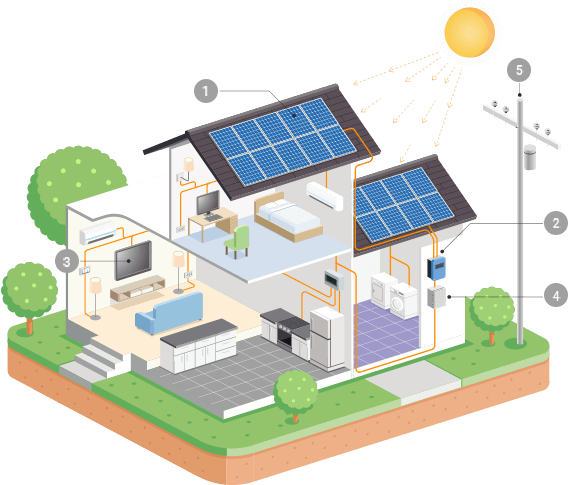

Photovoltaic ink has the potential to revolutionize the field of solar energy, making it possible to create affordable and flexible solar panels for a wide range of applications. These include:– Building-integrated photovoltaics – Solar-powered wearable devices – Portable solar chargers – Solar-powered sensors and IoT devices – Solar panels for off-grid and remote locations

In conclusion, photovoltaic ink is a promising technology with the potential to transform the way we harness solar energy. By following the steps outlined in this article, it is possible to create printable solar cells that are both versatile and cost-effective. As the technology continues to advance, we can expect to see an increasing number of innovative applications for photovoltaic ink in the near future.