How to Make Photovoltaic Solar Cells

Introduction

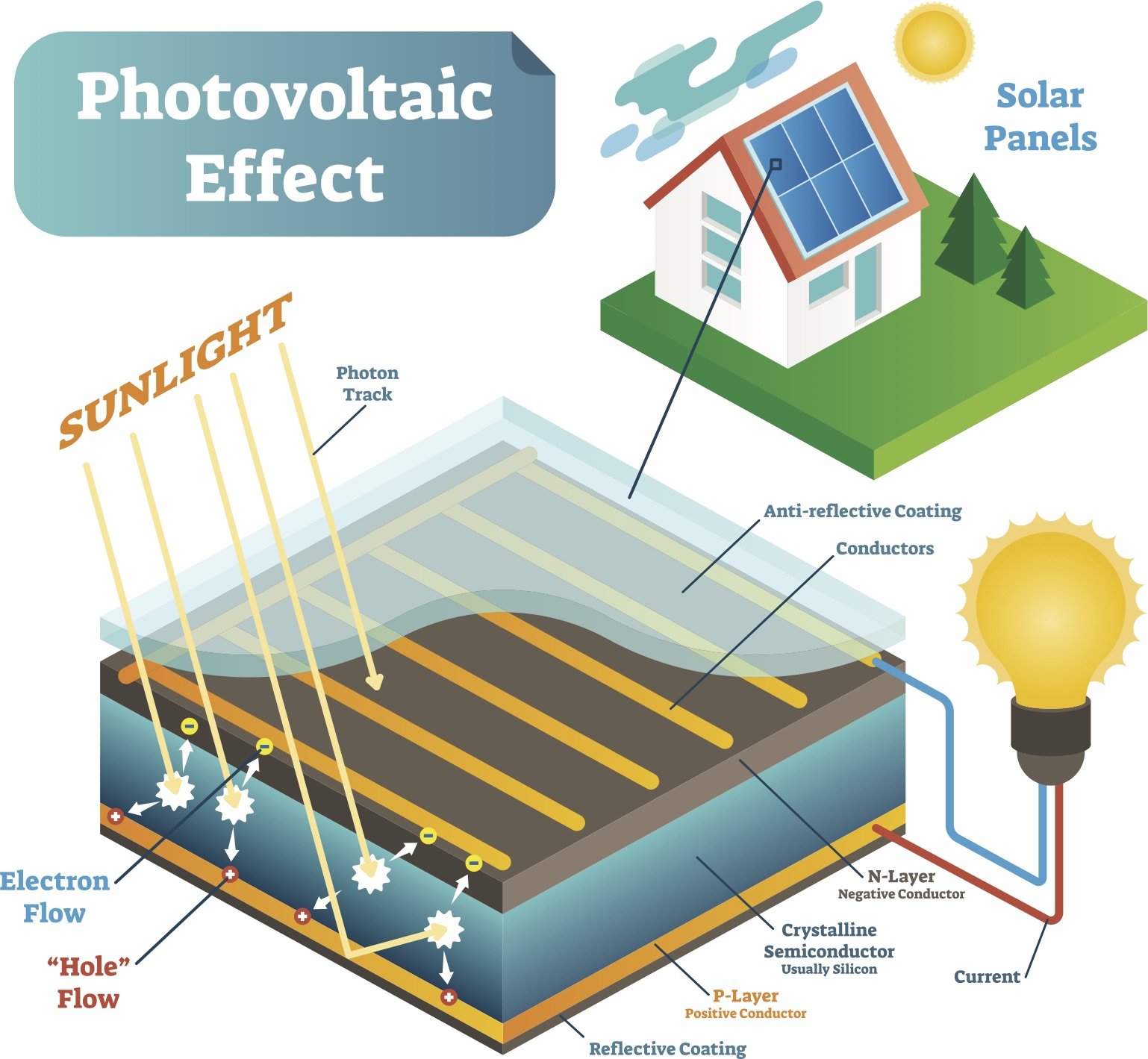

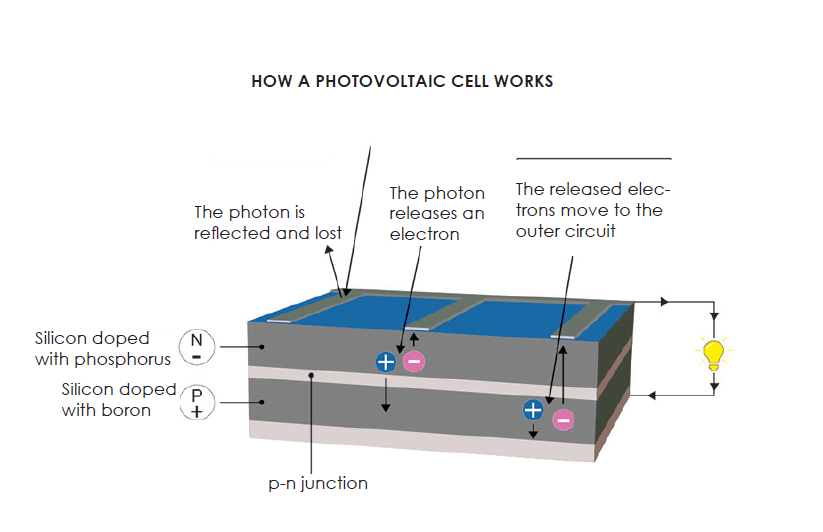

Solar energy is a renewable and sustainable source of power that can be harnessed through the use of photovoltaic solar cells. These cells are capable of converting sunlight directly into electricity, making them a popular choice for green energy production. In this article, we will discuss the process of making photovoltaic solar cells.

Gather Materials

1. Silicon Wafers

Silicon wafers are the key component of photovoltaic solar cells. These wafers are typically made from high-purity silicon and serve as the base for the cell’s semiconductor material.2. Semiconductor Material

The semiconductor material, often made from silicon as well, is applied to the silicon wafer to create the p-n junction necessary for the photovoltaic effect.3. Conductive Metal Contacts

Metal contacts are needed to allow the flow of electricity out of the solar cell. These contacts are typically made from materials such as silver or aluminum.4. Encapsulant

The encapsulant is used to protect the solar cell from environmental factors such as moisture and impact. It is often made from ethylene vinyl acetate (EVA).5. Backsheet

The backsheet serves as a protective layer for the back of the solar cell and is typically made from materials such as Tedlar or TPT.Assembly Process

1. Wafer Preparation

The silicon wafers are cleaned and treated to remove any impurities before the semiconductor material is applied.2. Application of Semiconductor Material

The semiconductor material is applied to the silicon wafer using processes such as deposition or diffusion to create the p-n junction.3. Metal Contact Deposition

Metal contacts are deposited onto the semiconductor material to allow for the collection of electricity generated by the photovoltaic effect.4. Encapsulation and Backsheet Application

The solar cell is then encapsulated with the encapsulant and the backsheet applied to provide protection against environmental factors.5. Quality Control and Testing

The finished solar cells are subjected to rigorous quality control measures to ensure they meet performance standards before being used in solar panels.Conclusion

In conclusion, the process of making photovoltaic solar cells involves gathering materials such as silicon wafers, semiconductor material, conductive metal contacts, encapsulant, and backsheet. These materials are then assembled through a series of steps including wafer preparation, semiconductor material application, metal contact deposition, encapsulation and backsheet application, and quality control and testing. By following this process, photovoltaic solar cells can be manufactured for use in solar panels to generate clean and sustainable energy from sunlight.