How to Make Silicon Photovoltaic Cells

Silicon photovoltaic cells, also known as solar cells, are devices that convert sunlight into electricity. They are a key component of solar panels and are becoming increasingly popular as a renewable energy source. In this article, we will discuss the process of making silicon photovoltaic cells.

Materials Needed

To make silicon photovoltaic cells, you will need the following materials:1. Silicon wafers 2. Conductive metal contacts 3. Anti-reflective coating 4. Encapsulation materials

Production Process

The production process of silicon photovoltaic cells involves several steps:1. Silicon Ingot Production

The first step in making silicon photovoltaic cells is to produce silicon ingots. This is done by melting high-purity silicon and then slowly cooling it to form a solid ingot.2. Wafer Production

The silicon ingots are then sliced into thin wafers using a diamond saw. These wafers are then polished to remove any imperfections and to create a smooth, flat surface.3. Doping

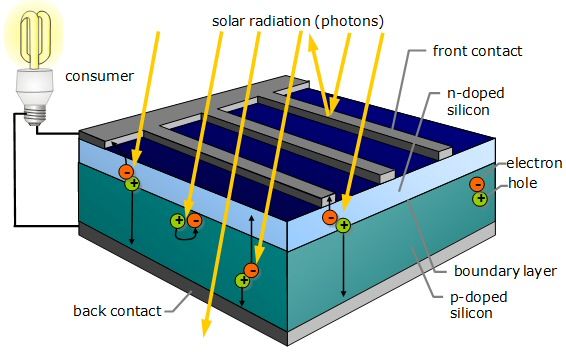

The next step is to dope the silicon wafers with specific impurities to create a p-n junction. This is done by diffusing phosphorus into one side of the wafer to create a negative (n-type) region, and boron into the other side to create a positive (p-type) region.4. Metal Contacts

Conductive metal contacts are then applied to the top and bottom of the silicon wafers. These contacts allow the flow of electricity generated by the solar cell.5. Anti-reflective Coating

An anti-reflective coating is applied to the top surface of the silicon wafers to reduce the reflection of sunlight and increase the absorption of photons.6. Encapsulation

Finally, the silicon photovoltaic cells are encapsulated in a protective material, such as glass or plastic, to protect them from the elements and to provide mechanical support.In conclusion, silicon photovoltaic cells are made by producing silicon ingots, slicing them into wafers, doping the wafers, applying metal contacts and anti-reflective coating, and encapsulating the cells. This process results in the production of solar cells that can generate electricity from sunlight.

By following these steps, manufacturers can produce high-quality silicon photovoltaic cells that can be used in solar panels to harness the power of the sun and provide clean, renewable energy for homes and businesses.