Photovoltaic solar cells, also known as solar photovoltaic cells, are devices that convert sunlight directly into electricity. These cells are made of various materials that enable them to harness the power of the sun and produce clean, renewable energy. In this article, we will explore the components and materials used in the production of photovoltaic solar cells.

Components of Photovoltaic Solar Cells

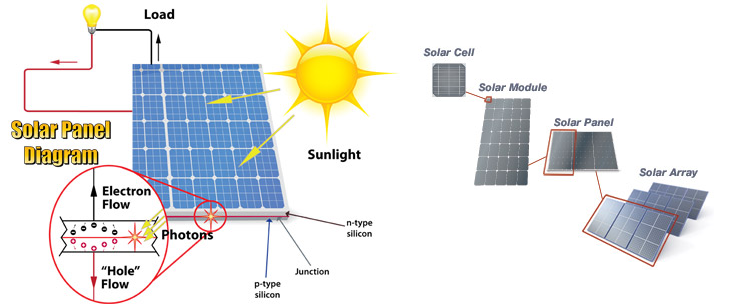

At their core, photovoltaic solar cells are made of semiconductor materials, which are responsible for converting sunlight into electricity. These materials are typically combined with other components to form a complete solar cell system, including:1. Photovoltaic Absorber Materials: These materials are designed to capture photons from sunlight and convert them into usable electrical energy. Common absorber materials include silicon, cadmium telluride, and copper indium gallium selenide.

2. Conductive Contacts: Photovoltaic cells require conductive contacts to transfer the generated electricity to an external circuit. These contacts are usually made of metal, such as silver or aluminum, and are placed on the top and bottom layers of the cell.

3. Encapsulation: Photovoltaic cells are encapsulated within a protective layer to ensure durability and longevity. This encapsulation provides weather resistance and protection against external elements.

Materials Used in Photovoltaic Solar Cells

The materials used in the production of photovoltaic solar cells are crucial to their performance and efficiency. Some of the key materials include:1. Silicon: Silicon is the most commonly used material in photovoltaic cells, making up the majority of solar panels on the market. It is a highly efficient semiconductor material with excellent light absorption properties.

2. Cadmium Telluride (CdTe): CdTe-based solar cells are known for their low-cost production and high efficiency. CdTe is a thin-film semiconductor material that offers good light absorption and can be deposited onto flexible substrates.

3. Copper Indium Gallium Selenide (CIGS): CIGS-based solar cells are gaining popularity due to their high efficiency and potential for low production costs. These cells are made of a thin layer of semiconductor material consisting of copper, indium, gallium, and selenium.

Manufacturing Process

The manufacturing process for photovoltaic solar cells involves the fabrication of semiconductor materials into functional cells. This process includes the following steps:1. Material Preparation: Semiconductor materials, such as silicon or thin-film compounds, are prepared and processed to create the necessary layers for the solar cell.

2. Cell Fabrication: The prepared materials are assembled into solar cell structures, including the deposition of contacts and encapsulation layers.

3. Module Assembly: Individual solar cells are connected and assembled into larger modules or panels to create a complete solar energy system.

4. Quality Control: Throughout the manufacturing process, rigorous quality control measures are implemented to ensure the reliability and efficiency of the photovoltaic cells.