What is a Silicon Photovoltaic Solar Cell Made Of

Introduction

Silicon photovoltaic solar cells, commonly known as solar panels, are devices that convert sunlight into electricity. These solar cells are made of various components that work together to generate renewable energy. In this article, we will explore the materials and structure that make up a silicon photovoltaic solar cell.

Silicon Wafer

Crystalline Silicon

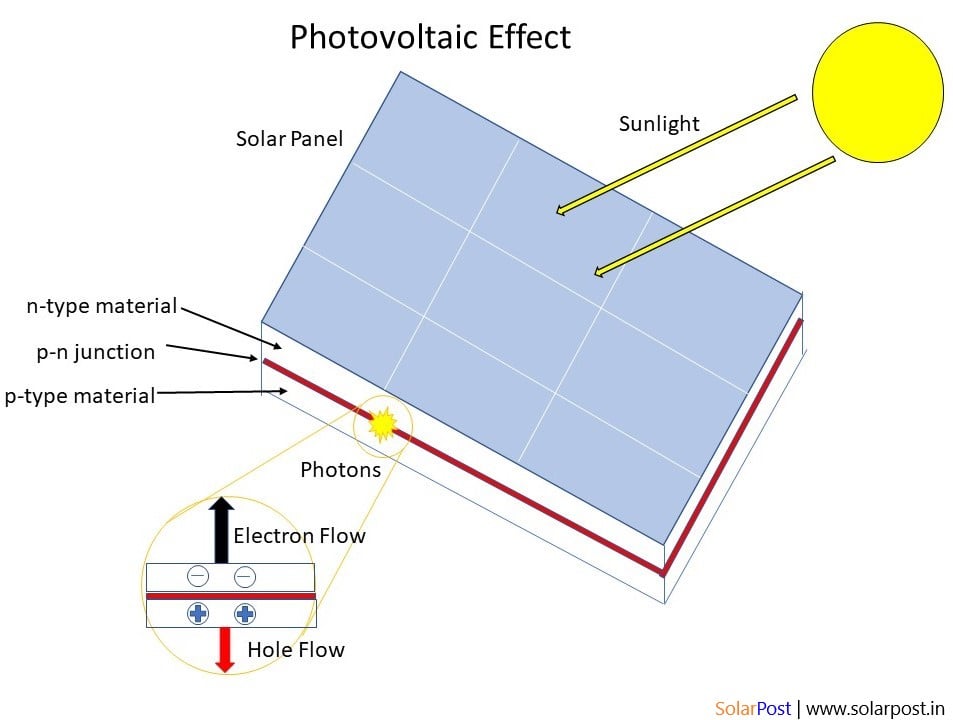

The key component of a silicon photovoltaic solar cell is the silicon wafer. The silicon used in solar cells is typically crystalline silicon, which is a highly pure form of the element. Crystalline silicon wafers are manufactured by growing large silicon crystals and then slicing them into thin discs. These wafers serve as the foundation of the solar cell and are responsible for absorbing sunlight and generating electricity.Doping

In order to create an electric field within the silicon wafer, small amounts of impurities are added to the material through a process called doping. This introduces extra electrons (n-type doping) or holes (p-type doping) into the silicon, creating a positive and negative side within the wafer. This separation of charge is essential for the flow of electricity within the solar cell.Metal Contacts

Front Contact

A transparent conductive material, such as indium tin oxide (ITO), is used as the front contact of the solar cell. This material allows sunlight to pass through to the silicon wafer while also enabling the flow of electrons. The front contact is responsible for collecting the generated electricity and transferring it out of the solar cell.

Back Contact

The back contact of a silicon photovoltaic solar cell is typically made of a metal grid or a thin layer of aluminum. This contact allows the flow of electrons to the external circuit and completes the electrical connection throughout the solar cell.Encapsulation Materials

EVA Encapsulation

To protect the delicate components of the solar cell from environmental factors, encapsulation materials are used to seal the cell. Ethylene-vinyl acetate (EVA) is a commonly used material for encapsulating solar cells. EVA encapsulation provides insulation, UV protection, and structural support for the solar cell.Glass Cover

The top layer of the solar cell is typically a tempered glass cover. This cover protects the solar cell from external elements such as rain, wind, and debris, while allowing sunlight to reach the silicon wafer. The glass cover also enhances the durability and longevity of the solar panel.In conclusion, a silicon photovoltaic solar cell is made of a crystalline silicon wafer, metal contacts, and encapsulation materials. These components work together to convert sunlight into electricity, making solar energy an increasingly popular and sustainable source of power.